Customised solutions

Faster production

Complex geometries

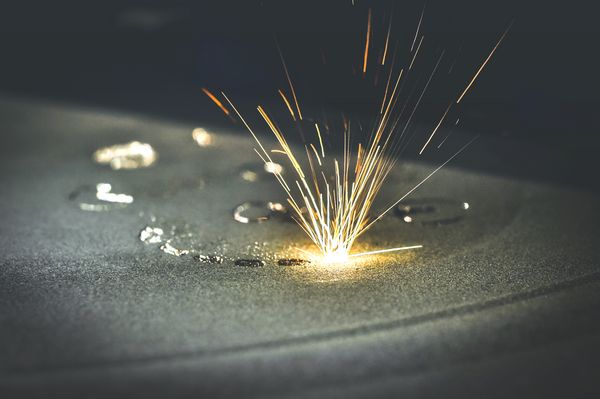

3D printing for metal - new technology for first-class results

SUHNER's advanced 3D printing technology opens up new horizons in 3D metal printing. The modern 3D printing solutions for metal offer the processing of metal and plastic in every conceivable shape. This makes the process ideal for applications in aviation, mechanical engineering and many other industries. With SUHNER as your partner, you can rely on manufacturing that pushes the boundaries of what is possible and brings your projects to life with unrivalled precision. Discover our 3D metal printing manufacturing processes at the highest level now!

Your solutions in 3D printing with metal

Components are increasingly required in small quantities and at short notice, whether for prototypes, new developments, spare parts that are no longer available or because the demand for customised series products is growing. This is where 3D printing for metal comes into play. With us, you can have your metal printing orders realised in 3D, straightforwardly and with professional support right from the start.

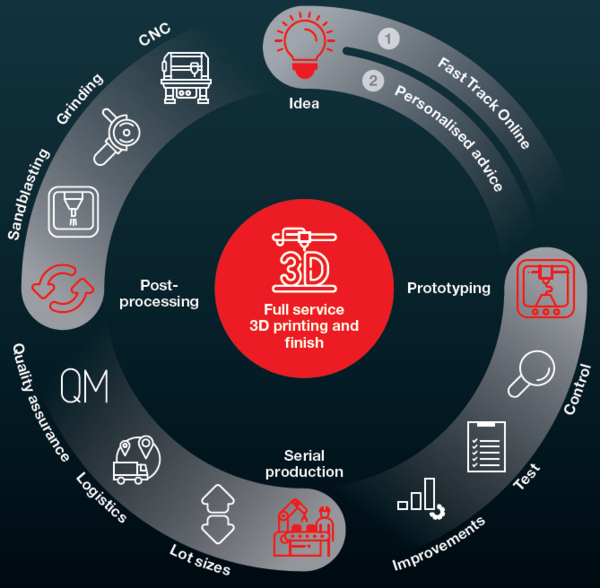

As a 360° solution provider, we offer you various printing technologies with our 3D metal printing, such as selective laser melting (SLM), fused deposition modelling (FDM) or fused filament fabrication (FFF). We support you throughout the entire project. Create perfection and utilise our expertise in metal printing!

Revolutionise your production with 3D printing

3D printing has fundamentally changed the production of metal components. Our state-of-the-art 3D printers utilise advanced processes such as laser melting and laser sintering to produce precise objects from the finest metal powder. This technology makes it possible to produce components with complex geometries and outstanding strength that would be almost impossible to realise using traditional methods. Our technology offers:

- Variety of materials: from robust metal to flexible plastic and specialised filaments such as PLA.

- Application flexibility: Use in numerous industries for the production of parts with specific properties and applications..

Diverse materials and techniques enable us to offer customised solutions for a wide range of requirements. Our expertise spans all stages of production, from the first layer to the finished product, ensuring a surface quality that meets your highest standards.

Materials for 3D printing

Printing technology selective lazer melting

Materials for metal 3D printing

Printing technology: Fused Deposition Modelling (FDM) or Fused Filament Fabrication (FFF)

3D printing for metal - this is how the process works with SUHNER

These steps are necessary for the successful realisation of 3D metal printing:

CAD data preparation

Appropriate preparation in CAD is the basic prerequisite for 3D production. In addition to providing the basis for production, the CAD models are also essential for the following services and optimisations.

Topology optimisation for function and manufacturability

Serves to improve the component shape (topology) in order, among other things, to save material while maintaining the component's strength. Or for simpler production without ‘loss of performance’.

Component distortion minimisation through simulation

Component distortion is costly, delays the project and the workpiece has to be manufactured again. With our simulation of the printing process, the distortion can be calculated and the geometry optimised.

Optimise support structures

The stability of the support structure is influenced by the density and pattern of the filling. It is not easy to find the optimum construction - either material is wasted or the structure becomes unstable. The choice of structure also influences the post process: a dense structure is more difficult to remove. We optimise all support structures for you.

Tensile testing Tests

At SUHNER, test specimens are tested with a tensile testing machine from ‘Zwick&Roell’ to ensure quality and functionality. In addition to quality and functionality, these also provide information on mechanical strength, depending on the printing process.

Print optimisation

Print optimisation makes a significant contribution to achieving consistent production quality as well as significant cost savings. In the case of complex workpieces, this counteracts misprints. It also achieves the best surface quality.

Direct and digital

Fast track for rapid prototyping and production

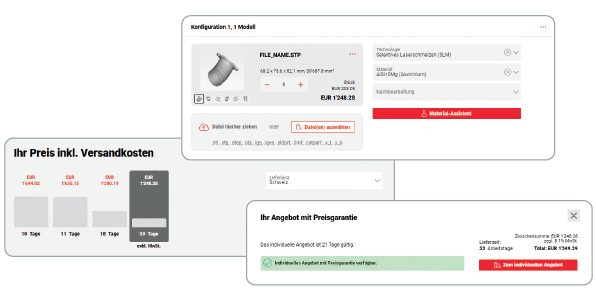

Use our online portal

All 3D printed parts from a single source. Take advantage of SUHNER's global manufacturing network with a wide range of additional services and manufacturing processes. Get a quote in four clicks and a finished workpiece in just a few days.

- The process is fully digital and available around the clock.

- Full transparency: delivery time, price and production status are immediately visible. Quotations have a 21-day price guarantee.

- Our platform supports the file formats of most CAD applications: .sti, .stp, .step, .obj, .igs, .iges, .sldprt, .3mf, .catpart, .x_t, .x_b

- The available technologies and the extensive selection of materials are described in detail so that you have a solid basis for decision-making.

- The data is automatically checked and simple geometry errors are corrected immediately.

From the design to the finished part: our service

At SUHNER, we support you from the initial concept of your 3D printing projects right through to realisation. Our goal is to bring your vision to life with the highest precision and efficiency, regardless of whether it is a one-off or series production. We provide solutions for the creation of your customised metal workpieces and metal components. In doing so, we provide our innovative expertise in process cost optimisation in metal processing at all stages from design to delivery of the final product. In addition to the large selection of our first-class products, we also offer you a comprehensive service with:

- Multiple payment options: Flexibility with every order

- Rapid dispatch: Reliable delivery of your orders.

- Dedicated customer support: Contact us at any time. We are happy to support you with our expertise.

Discover the full range of Suhner Components to make your projects a success. Browse through our news and marvel at the exciting possibilities that 3D printing has in store for your company. Be part of the transformation of 3D metal printing with SUHNER and contact us today!

Contact

Ready to simplify your processes?

Our team is here to support you on your journey to success. Whether it's questions, customised advice or simply an exchange - we're here for you.

Discovering, shaping and changing together

As your partner, we stand for innovation and quality. Let us develop your potential together.

Your personal contact to success

Our solutions are designed to help you unlock maximum value, improve product performance, optimise manufacturing processes and stay one step ahead of the competition in your respective industries.

Want to take your business to the next level?

We're just a click or call away.

Write to us today:

Follow us on